Introduction

The use of radioactive material, radiation-producing machines, and nuclear technologies play a huge role in our lives everyday. There are countless uses for these technologies in our society, and some that you may not be thinking of. Every company that uses radioactive materials, radiation-producing machines, or nuclear technologies must comply with federal and/or state regulations. Whether your license is overseen by the Nuclear Regulatory Commission (NRC) or an Agreement State, inspections are a fact of life.

The best way to ensure a smooth inspection is to have a Radiation Protection Program (RPP) that is not only compliant but also audit-ready.

This guide will explain, in detail, how to Developing an Audit Ready Radiation Protection Program—covering NRC requirements, Agreement State expectations, and practical steps businesses can take.

Why Radiation Protection Programs Matter

A Radiation Protection Program is the foundation to ensure regulatory compliance with federal, state, and local statutes. It demonstrates how your organization ensures radiation exposures are kept As Low As Reasonably Achievable (ALARA), and how safety is integrated into daily operations and simply not an after thought.

If your organization does not have an effective RPP, you could be subjected to the following:

- Your license could be suspended or revoked.

- Employees may be overexposed to radiation.

- Regulatory fines could harm your business reputation and finances.

This list is not all inclusive, but gives examples of how regulators expect that your RPP is tailored to your operations, not a generic template. If you do not follow what is expected, then you can be subjected to these penalties or worse ones.

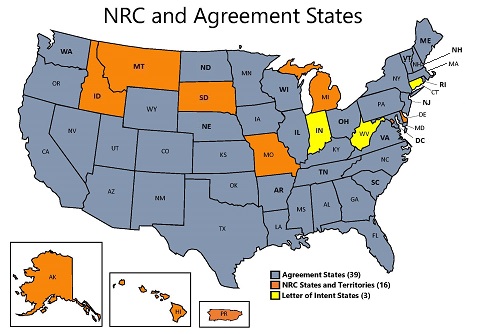

Who Regulates Radiation Protection?

Federal Oversight – The NRC

- The Nuclear Regulatory Commission regulates all nuclear reactors, materials in non-Agreement States, and activities on federal property.

- Key rules: 10 CFR Part 19 (Notices, Instructions, and Reports to Workers) and 10 CFR Part 20 (Standards for Protection Against Radiation).

- The NRC does not regulate X-ray machines or particle accelerators. The NRC only regulates accelerators if they are under a radioactive material license. Examples are medical isotope production.

State Oversight – Agreement States

- Thirty-nine Agreement States regulate most radioactive material licenses within their borders.

- States must adopt rules compatible with the NRC but can be stricter.

- State inspectors review the same core program elements but may pay closer attention to recordkeeping, training, and security.

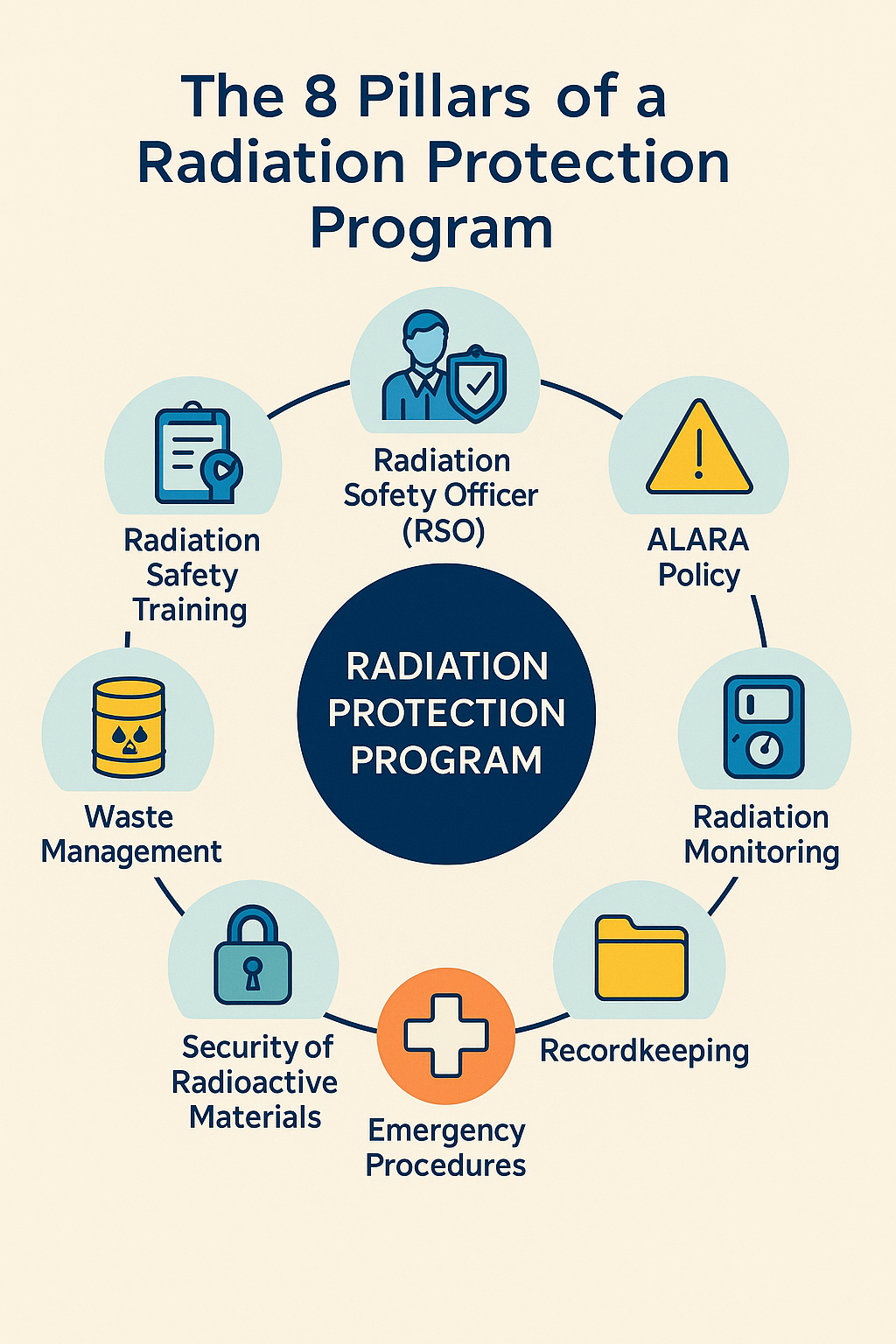

Core Elements of a Radiation Protection Program

Whether you’re in an NRC state or Agreement State, regulators will expect to see specific core components. These can be organized into ‘Pillars of Radiation Protection’.

- Radiation Safety Officer (RSO)

- A qualified individual responsible for program oversight.

- Must have documented training and authority.

- Are appointed by organizational senior leadership

- ALARA Policy

- Written procedures demonstrating how exposures are minimized.

- Includes engineering controls, time/distance/shielding strategies, and dose tracking.

- Radiation Safety Training

- Initial and annual training for all workers.

- Specialized training for staff who handle radioactive sources.

- Radiation Monitoring

- Personal dosimetry for exposed workers.

- Area surveys and contamination checks.

- Recordkeeping

- Dose records, training logs, equipment calibration, and leak tests.

- Must have good organization and easily accessible for inspectors.

- Emergency Procedures

- Spill response, lost source reporting, and contaminated patient handling.

- Posted instructions in work areas.

- Waste Management

- Procedures for decay-in-storage, licensed disposal, or return to manufacturer.

- Waste logs kept up to date.

- Security of Radioactive Materials

- Locked storage and restricted access.

- Two-person rules for higher category sources.

Common Audit Findings (Federal & State)

Auditors often focus on areas where facilities stumble. Knowing these in advance helps you strengthen weak spots. Understanding these weaknesses can help prepare for inspections and prevent ‘low hanging fruit’ that is easy for regulators to find.

- Expired Licenses or Amendments Not Filed

- Incomplete Training Records

- Missing or Late Dosimetry Reports

- Survey Meters Not Calibrated Annually

- Unsecured Radioactive Sources

- Emergency Procedures Not Posted

- Waste Disposal Records Incomplete

Now that you understand why having a sound radiation protection program, let’s look at how to build one.

Step-by-Step Guide to Building an Audit-Ready RPP

Appoint and Empower an RSO

- The RSO must have technical knowledge and authority to enforce safety rules.

- Document the RSO’s responsibilities in writing.

Write Your ALARA Policy

- Outline how exposures will be kept as low as possible.

- Include thresholds for investigation when dose levels are exceeded.

Develop a Training Program

- Create onboarding training for new employees.

- Schedule annual refreshers.

- Document every session with attendance logs and content covered.

Implement Monitoring Systems

- Issue dosimeters to workers.

- Perform area surveys using calibrated meters.

- Maintain calibration certificates and leak test results.

- May not be a requirement if licensees can prove exposures are less than 10% of regulatory limits

Establish Recordkeeping Procedures

- Use both paper and digital backups.

- Organize files by category: training, dosimetry, surveys, waste, equipment.

- Keep records in a central location.

Prepare Emergency Response Plans

- Include spill response, lost source procedures, and medical emergency handling.

- Train staff with drills at least annually.

Create a Waste Management System

- Set clear decay-in-storage policies.

- Record every waste transfer and disposal.

- Partner with licensed disposal contractors when necessary.

Secure All Radioactive Materials

- Lock all sources when not in use.

- Post warning signs and restrict access.

- For higher risk sources, implement double-lock security.

Conduct Internal Audits

- Review your own program quarterly.

- Address gaps before inspectors arrive.

Maintain Continuous Communication

- Subscribe to NRC and state newsletters for regulation updates.

- Keep open lines with inspectors and state program officers.

Preparing for an Audit

Audits are not meant to punish but to ensure compliance. Preparation is key.

- Notify staff: Ensure everyone knows their roles and expectations.

- Prepare documents: Have all records organized and accessible in a central location.

- Conduct mock interviews: Inspectors often ask employees about safety procedures.

- Walkthrough readiness: Do a pre-inspection tour to fix signage or housekeeping issues.

Federal vs. State Inspection Nuances

- NRC Audits: More standardized, heavy focus on federal regulations (10 CFR).

- Agreement State Audits: May have additional state-specific forms, stricter recordkeeping checks, or environmental considerations.

- Common Ground: Both require demonstration of ALARA, strong documentation, and clear emergency plans.

Real-World Examples

Medical Imaging Facility

- Violation: Missing training logs.

- Result: NRC issued a fine and required immediate retraining.

- Lesson: Keep training records current and accessible.

Industrial Radiography Company

- Violation: Survey meter calibration overdue.

- Result: State suspended license until compliance restored.

- Lesson: Maintain calibration logs and schedule reminders.

University Research Lab

- Violation: Waste records incomplete.

- Result: Audit required corrective action plan.

- Lesson: Document every waste disposal step.

Building a Culture of Safety

Passing audits isn’t just about paperwork. Inspectors also look for signs that employees truly understand safety.

- Leadership must reinforce the importance of radiation safety.

- Employees should feel empowered to stop unsafe work.

- Training should be practical, not just a formality.

- Celebrating safety milestones encourages compliance.

Conclusion

A strong Radiation Protection Program is your best defense against violations and fines. By combining federal standards, state requirements, and internal best practices, businesses can create a program that protects employees, satisfies regulators, and builds trust with clients.

The most important takeaway: make your RPP a living document, not a binder on a shelf. Update it, practice it, and use it daily. That’s how you pass any audit.

0 Comments