Radiation safety goes beyond simply meeting regulatory limits. The concept known as ALARA, or As Low As Reasonably Achievable, is the foundation of modern radiation protection.

The Nuclear Regulatory Commission defines ALARA as making every reasonable effort to maintain exposures far below dose limits, consistent with the purpose of the activity.

When organizations apply ALARA effectively, they create safer workplaces, meet regulatory requirements, and reduce long-term risk. Let’s discuss practical ways to keep doses ALARA within your organization.

Understanding the ALARA Principle

What ALARA Means

ALARA means keeping radiation exposure as low as reasonably achievable while considering technology, cost, and operational needs. It is both a regulatory requirement and a professional standard of practice.

Why ALARA Matters

Even small amounts of ionizing radiation can increase the risk of long-term health effects. Reducing exposure whenever possible helps protect workers, patients, and the public.

The Three Core Principles

- Time – Limit the time spent near radiation sources.

- Distance – Stay as far away from sources as possible.

- Shielding – Use barriers such as lead, concrete, or specialized materials.

These three controls form the practical foundation of ALARA in every radiation environment.

Building a Safety Culture

ALARA works best when safety is part of organizational culture. It requires leadership support, employee awareness, and clear accountability.

Integrating ALARA into a Radiation Protection Program

Leadership and Accountability

Appoint a qualified Radiation Safety Officer (RSO) with authority to enforce ALARA goals. Leadership must support this role with resources, staffing, and time for safety activities.

Written ALARA Policy

Every facility using radiation should have a written ALARA policy. This document should include measurable objectives, dose tracking methods, and responsibilities for maintaining compliance.

Employee Training and Awareness

Training is essential. Employees should understand how their daily actions affect radiation exposure. Use examples and real data to make the training relevant.

Monitoring and Feedback

Establish regular reviews of personal and area dose data. Set internal investigation levels below regulatory limits to identify and correct problems early.

Engineering and Administrative Controls

Use process mapping to identify high-dose tasks. Redesign workflows, add shielding, and adjust schedules to reduce exposures.

Practical Ways to Reduce Radiation Exposure

Reduce Time Near Sources

Plan work before entering radiation areas. Gather all tools and equipment in advance. Use practice runs in non-radiation zones to reduce real exposure time.

Increase Distance

Whenever possible, work remotely or use extension tools to increase distance from sources. Even a few extra feet can significantly reduce dose rates.

Improve Shielding

Evaluate current shielding materials and add mobile or fixed barriers where needed. Check existing shielding regularly for cracks or gaps.

Strengthen Administrative Controls

Use access restrictions, warning signs, and checklists to reinforce safe behavior. Schedule high-dose work during times of minimal occupancy.

Implement Monitoring and Alarms

Equip workers with personal dosimeters and ensure area monitors are calibrated. Set alarms to warn of elevated dose rates or equipment faults.

Upgrade Equipment

Modern equipment often emits less radiation due to improved efficiency and built-in shielding. Replace older systems when feasible to improve both safety and performance.

ALARA in Different Work Environments

Healthcare

In hospitals, use ALARA to minimize patient and staff exposure. Adjust imaging parameters to use the lowest dose that produces diagnostic quality images.

Industrial Radiography

Operators should rely on remote-handling tools, robust shielding, and controlled work areas. Routine inspections ensure radiation enclosures function properly.

Research and Academic Laboratories

Even low-activity sources can pose risks. Maintain strict contamination control and conduct regular wipe tests in work areas.

Environmental and Public Exposure

Facilities should limit environmental emissions and monitor nearby public areas. ALARA applies to all potential exposure pathways, including air, water, and waste.

Monitoring, Auditing, and Continuous Improvement

Set Investigation Levels

Define dose thresholds below regulatory limits to trigger review. For example, investigate when any worker reaches 25% or 50% of the annual limit.

Conduct Routine Audits

Perform internal audits of your entire radiation protection program. Review training, equipment calibration, and radiation survey results.

Prepare for Regulatory Inspections

Keep all ALARA documentation organized and ready for inspection. Inspectors will check how policies are implemented, not just whether they exist.

Analyze Data and Provide Feedback

Use exposure data to identify trends and corrective actions. Share results with workers to promote awareness and reinforce progress.

Measuring ALARA Performance

Key Performance Indicators

Track dose levels for individuals and departments. Compare results to previous periods and establish improvement targets.

Benchmarking

Compare your performance with other facilities or national averages. Benchmarking helps identify realistic improvement goals.

Communication and Recognition

Share ALARA achievements in safety meetings or newsletters. Recognize teams that reduce doses while maintaining quality or productivity.

Avoiding Common ALARA Mistakes

Assuming Compliance Equals Safety

Staying below regulatory limits does not guarantee doses are as low as possible. Always look for ways to improve.

Overlooking Internal Contamination

External exposure gets attention, but inhalation or ingestion of radioactive material can be more serious. Monitor both internal and external doses.

Lack of Employee Engagement

Workers must believe in the importance of ALARA. Encourage participation by explaining how dose reduction directly benefits them.

Neglecting Equipment Maintenance

Unmaintained equipment may produce unnecessary radiation. Regular servicing ensures optimal performance and lower exposure.

Ignoring Trends in Dose Data

Failing to review dose trends can lead to gradual exposure increases. Early detection prevents future regulatory problems.

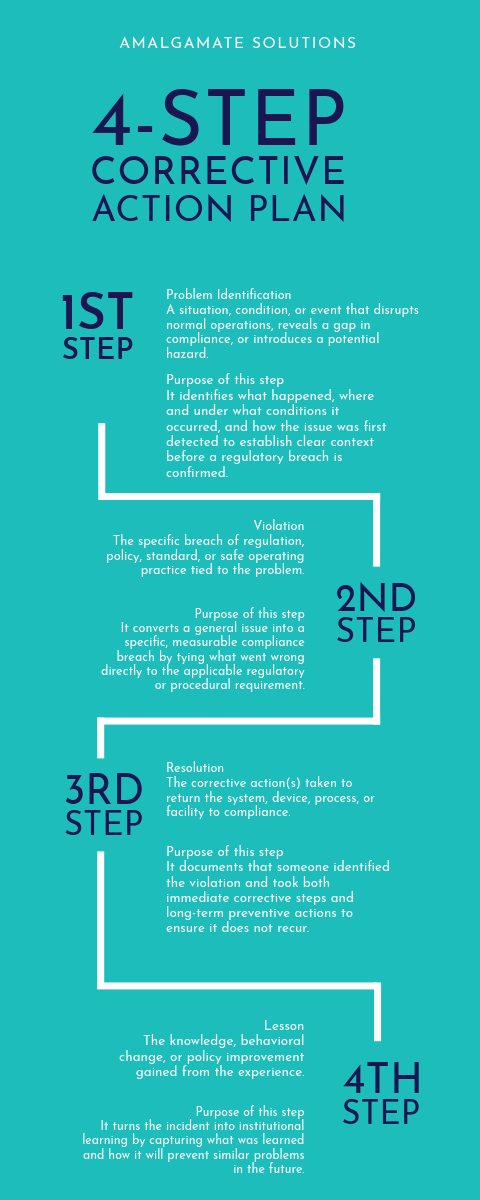

Case Study: ALARA in Practice

A medical center noticed rising staff doses during interventional radiology procedures. Though all exposures remained below regulatory limits, leadership decided to act.

Problem: Staff spent long periods close to patients during fluoroscopy.

Violation: The ALARA goal was not being met due to excessive time near the source and inadequate use of barriers.

Resolution:

- Moved control panels farther from tables to increase distance.

- Installed ceiling-mounted lead shields and added mobile barriers.

- Trained staff to plan procedures efficiently to reduce time in high-dose zones.

- Introduced electronic dosimetry badges that displayed real-time exposure data.

Result: Average staff doses dropped by 50% within nine months. The facility achieved compliance and strengthened its safety culture.

Lesson: ALARA success requires proactive action, ongoing monitoring, and employee participation, even when exposures appear acceptable.

Maintaining ALARA Awareness

Regular Refresher Training

Provide refresher training each year to remind workers of ALARA goals and procedures. Update content to include new technologies and lessons learned.

Continuous Communication

Post ALARA reminders in work areas and discuss dose performance in regular safety meetings. Visible commitment encourages continuous improvement.

Encourage Reporting and Innovation

Create a simple process for employees to suggest ALARA improvements. Many practical ideas come from those who perform the work daily.

Leadership Example

Supervisors and managers should model safe behavior. Workers take cues from leadership commitment to safety and ALARA principles.

Building a Sustainable ALARA Program

To make ALARA part of long-term organizational culture, integrate it into every process—from procurement to decommissioning.

- Include ALARA reviews in design and project planning.

- Require dose evaluations for new equipment or procedures.

- Review the program annually and adjust goals as conditions change.

When ALARA becomes routine, the organization builds a reputation for safety, professionalism, and compliance excellence.

Conclusion

The ALARA principle transforms radiation protection from a compliance requirement into a living, practical system for dose reduction.

By focusing on time, distance, and shielding—and embedding training, monitoring, and feedback—you ensure that safety becomes second nature.

Implementing ALARA means protecting workers, building trust, and staying ahead of regulatory challenges. Continuous improvement keeps your program effective and your workplace safe.

Start small: review one task, measure results, and make incremental improvements. Over time, those steps create measurable reductions and a strong culture of radiation safety.

0 Comments