Introduction

Radiation and nuclear material are essential tools across industries—from medical imaging to industrial radiography to nuclear power. While the benefits are significant, the risks of mishandling radioactive materials are equally serious. To protect workers, the public, and the environment, federal and state regulators such as the Nuclear Regulatory Commission (NRC) and Agreement State agencies enforce strict rules.

However, many businesses still face concerns of radiation safety violations. These violations can result in fines, shutdowns, or even loss of a license to operate. Fortunately, most of these issues are avoidable if organizations understand the root causes and take the right steps to build strong prevention strategies.

The goal is to help you understand common radiation safety violations and how to avoid them for your business. Let’s jump in and discuss the overall regulatory landscape and how to navigate it.

Understanding the Regulatory Landscape

Before we dive into violations, it’s important to understand who enforces radiation safety rules in the United States.

- The NRC (Nuclear Regulatory Commission): Regulates radioactive materials, nuclear reactors, and fuel cycle facilities in states without their own regulatory agreements.

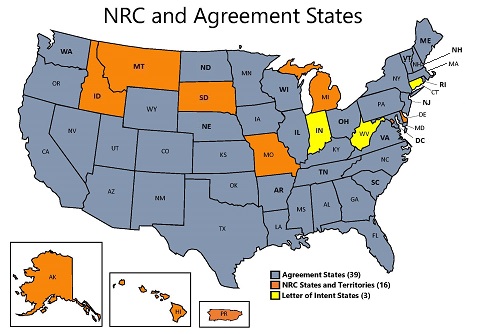

- Agreement States: Thirty-nine states have taken on regulatory responsibility for certain radioactive materials. Their rules must be compatible with the NRC’s but may be more restrictive.

- OSHA (Occupational Safety and Health Administration): Oversees workplace safety, including radiation exposure in some scenarios.

- EPA (Environmental Protection Agency): Regulates environmental aspects such as effluent releases and radon.

- Department of Energy: Possesses and regulates nuclear material at National Laboratories and other Department of Energy locations.

Every organization must know which authority regulates their operations to ensure they’re following the correct set of rules. You will need to understand if you fall under NRC or Agreement States for the licensing of radioactive and/or nuclear material.

Common Radiation Safety Violations

Radiation safety violations fall into recurring categories that inspectors may frequently note during audits.

1. Failure to Maintain Proper Licensing

Companies who don’t fully understand or have appropriately trained staff may operate with an expired licenses or use radioactive materials outside the scope of their license. This includes:

- Not renewing the radioactive materials license on time.

- Using equipment or isotopes not covered in the original application.

- Transferring materials without authorization.

How to avoid it:

- Maintain a compliance calendar with license expiration dates.

- Assign responsibility to a Radiation Safety Officer (RSO) for license oversight.

- Update the license when new materials or uses are added.

2. Inadequate Radiation Protection Programs

Regulations require businesses to implement a Radiation Protection Program (RPP) that demonstrates the ALARA (As Low As Reasonably Achievable) principle. Common violations include:

- Lack of written procedures.

- No evidence of ALARA implementation.

- Outdated or incomplete training records.

How to avoid it:

- Develop a written RPP tailored to your facility.

- Document ALARA practices, such as shielding, time, and distance measures.

- Review and update the RPP annually.

3. Poor Recordkeeping

Inspectors often find missing or incomplete records. Examples include:

- Dosimetry reports not filed.

- Training attendance sheets missing signatures.

- Equipment calibration logs absent.

How to avoid it:

- Use digital recordkeeping systems with automatic backups.

- Train staff on the importance of documentation.

- Schedule quarterly internal audits of records.

4. Failure to Monitor Radiation Exposure

Violations occur when organizations fail to monitor or report occupational doses. Issues include:

- Not providing dosimeters to exposed workers.

- Ignoring action levels when exposures exceed thresholds.

- Delayed reporting of overexposures.

How to avoid it:

- Issue badges or dosimeters to all monitored staff.

- Review exposure reports monthly.

- Immediately investigate any unusual readings.

5. Untrained or Insufficiently Trained Workers

Training is a frequent deficiency. Examples include:

- New hires working with radioactive material without orientation.

- Annual refresher training not documented.

- RSOs without updated certifications.

How to avoid it:

- Require initial and annual radiation safety training.

- Keep records of all training sessions.

- Provide additional training when new equipment or isotopes are introduced.

6. Improper Storage and Security

Radioactive materials must be secured to prevent theft or misuse. Violations include:

- Storage areas left unlocked.

- Sources stored in combustible or insecure cabinets.

- Lack of proper signage.

How to avoid it:

- Store sources in locked, fireproof cabinets.

- Post radiation hazard signs in visible areas.

- Use access control systems for high-risk materials.

7. Equipment Calibration and Maintenance Failures

Common issues include:

- Survey meters not calibrated annually.

- Leak tests not performed on sealed sources.

- Imaging machines used past due maintenance cycles.

How to avoid it:

- Schedule equipment calibration annually (or per manufacturer/NRC requirements).

- Keep maintenance logs and certificates.

- Conduct routine checks before use.

8. Improper Disposal of Radioactive Waste

Businesses sometimes discard radioactive waste with normal trash. Others fail to maintain waste decay-in-storage records.

How to avoid it:

- Segregate radioactive waste from other waste streams.

- Train staff on proper disposal protocols.

- Partner with licensed disposal contractors.

9. Failure to Report Incidents or Abnormal Conditions

Reporting delays can result in serious violations. Examples:

- Failure to notify regulators of lost sources.

- Not reporting accidental exposures.

- Delaying incident reports beyond required timeframes.

How to avoid it:

- Train staff on what constitutes a reportable event.

- Keep NRC/State contact numbers posted in work areas.

- Designate the RSO to handle incident communication immediately.

10. Lack of Emergency Preparedness

Some organizations do not have adequate response plans for spills, lost sources, or contaminated workers.

How to avoid it:

- Develop written emergency procedures.

- Conduct regular drills with staff.

- Equip facilities with spill kits, PPE, and decontamination supplies.

Section 3: Why These Violations Happen

Most violations arise not from negligence but from:

- Limited staff knowledge of regulations.

- High turnover leading to gaps in training.

- Over-reliance on one person (RSO) without backups.

- Failure to keep up with regulatory updates.

By understanding the root causes, organizations can design systems that reduce risk.

Section 4: Step-by-Step Guide to Avoiding Violations

Here’s a practical checklist businesses can follow:

- Assign a Qualified Radiation Safety Officer

- The RSO should have appropriate training and authority.

- Develop a Comprehensive Radiation Protection Program

- Address exposure limits, ALARA, waste management, emergency procedures, and security.

- Maintain an Active Licensing System

- Track license expiration and update scope as operations change.

- Train All Staff Regularly

- Provide onboarding, refresher, and situational training.

- Implement Strong Recordkeeping

- Use cloud systems to store dosimetry, training, and calibration records.

- Conduct Internal Audits

- Perform quarterly compliance checks.

- Stay Current with Regulatory Changes

- Subscribe to NRC and Agreement State bulletins.

- Prepare for Inspections

- Keep documentation accessible.

- Train staff on inspection protocols.

Section 5: Real-World Case Examples

- Medical Facility Fined for Poor Training: A radiology clinic was cited when staff operated an X-ray unit without documented training. The penalty was financial but also damaged public trust.

- Industrial Radiography Company Lost License: An inspection found unsecured sources in a van. The NRC revoked their license, shutting down the business.

- University Laboratory Incident: A misplaced radioactive source went unreported for weeks, leading to regulatory enforcement and loss of funding.

Each case reinforces that proactive compliance is always cheaper than violations.

Section 6: Building a Culture of Radiation Safety

True compliance goes beyond meeting minimum requirements. The most successful organizations build a safety culture where every employee understands their role.

Tips to foster this culture:

- Leadership communicates the importance of radiation safety.

- Employees feel empowered to report concerns.

- Safety metrics are tracked and celebrated.

Conclusion

Radiation safety violations can be costly, disruptive, and dangerous. The good news is that nearly all of them are preventable with strong leadership, clear procedures, ongoing training, and rigorous recordkeeping.

By learning from the most common mistakes—such as poor licensing management, inadequate training, or lack of emergency preparedness—U.S. businesses can avoid regulatory fines and, more importantly, protect workers and communities.

The key message: Compliance is not just about avoiding penalties—it’s about building a safer, more resilient organization.

Amalgamate Solutions is your partner in regulatory affairs and compliance. Equipped with regulatory experts to help you navigate the ever changing requirements from federal, states, and international regulatory entities.

0 Comments